Machine Vision Lighting Techniques

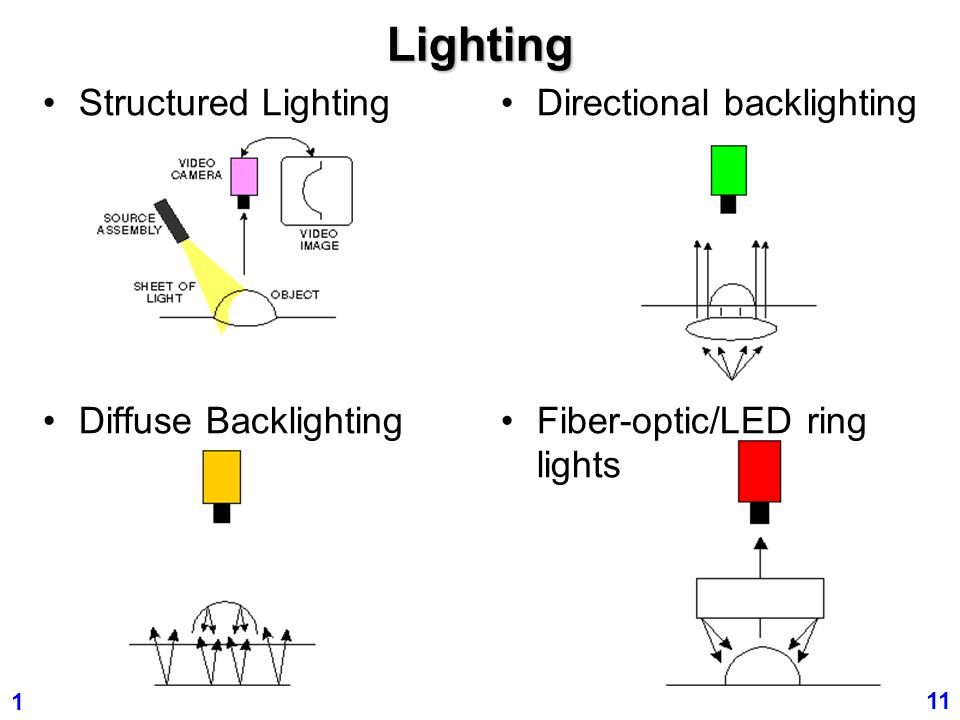

For this blog i will focus on the seven main lighting techniques continue reading how to select the best lighting.

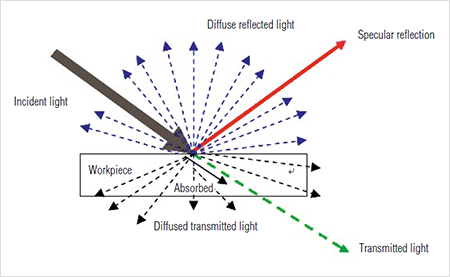

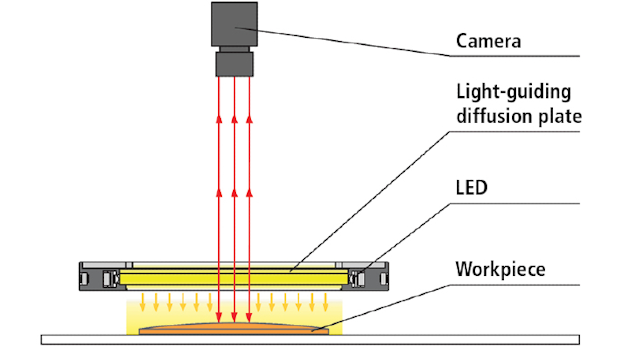

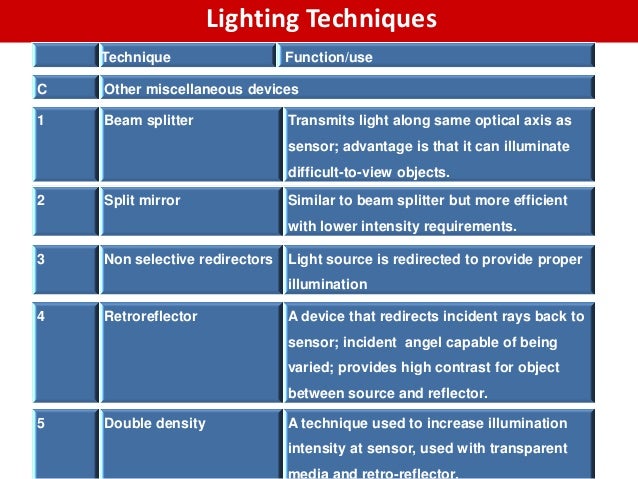

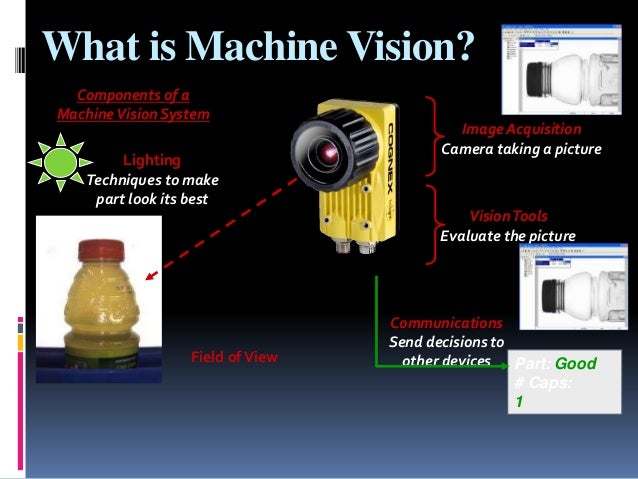

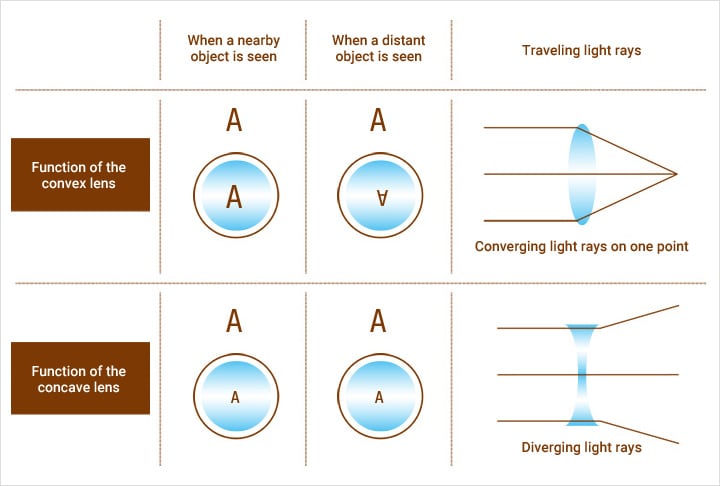

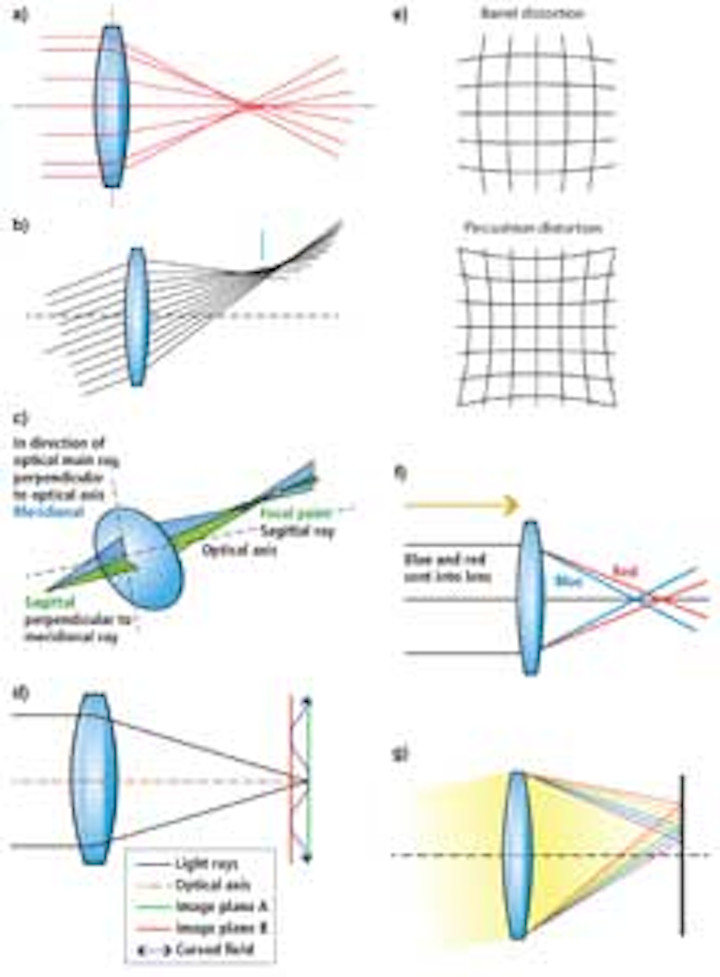

Machine vision lighting techniques. According to liebo three components impact a machine vision system s performance. To design an effective vision lighting solution you need a thorough analysis of the inspection environment including sample presentation and sample light interactions in addition to an understanding of illumination types techniques geometry filtering sensor. The following sequence. Criteria as applied to machine vision.

Smart vision lights is the main designer and manufacturer of led lighting solutions for any kind of machine vision or automation camera software. The key to deploying a robust machine vision application in a factory automation setting is ensuring that you create the necessary environment for a stable image. Six lighting techniques that will improve performance. 2 comparison and contrast of common vision lighting sources.

The three areas you must focus on to ensure image stability are. The importance of lighting may come as a surprise but it s logical when you consider its impact on the image. Lighting lensing and material handling. For example whereas led lighting has a longer life expectancy quartz halogen lighting may be the choice for a particular inspection because it offers greater intensity.

The quality and appropriateness of lighting are critical aspects for creating a robust and timely vision inspection. It s used to add contrast to matte surfaces similar to paper or cardboard outline edges or spotlight floor options. Lensing and camera selection 15. A variety of parameters can determine the light source which creates an interaction with the test object and its individual material properties.