Manual Slide Gate Valve Design

1 5 gate valves with plastic paddles 30 products.

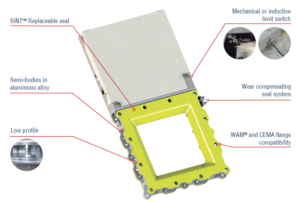

Manual slide gate valve design. Ideal for handling dry bulk material in gravity flow dilute phase or dense phase pneumatic conveying applications. Once a knife gate s seals wear they start to leak and must be replaced. See more ideas about sliding gate gate gate design. Ideal for dry bulk material handling meyer made knife gates and slide gates are reliable and designed to isolate airlock feeders below from hoppers above.

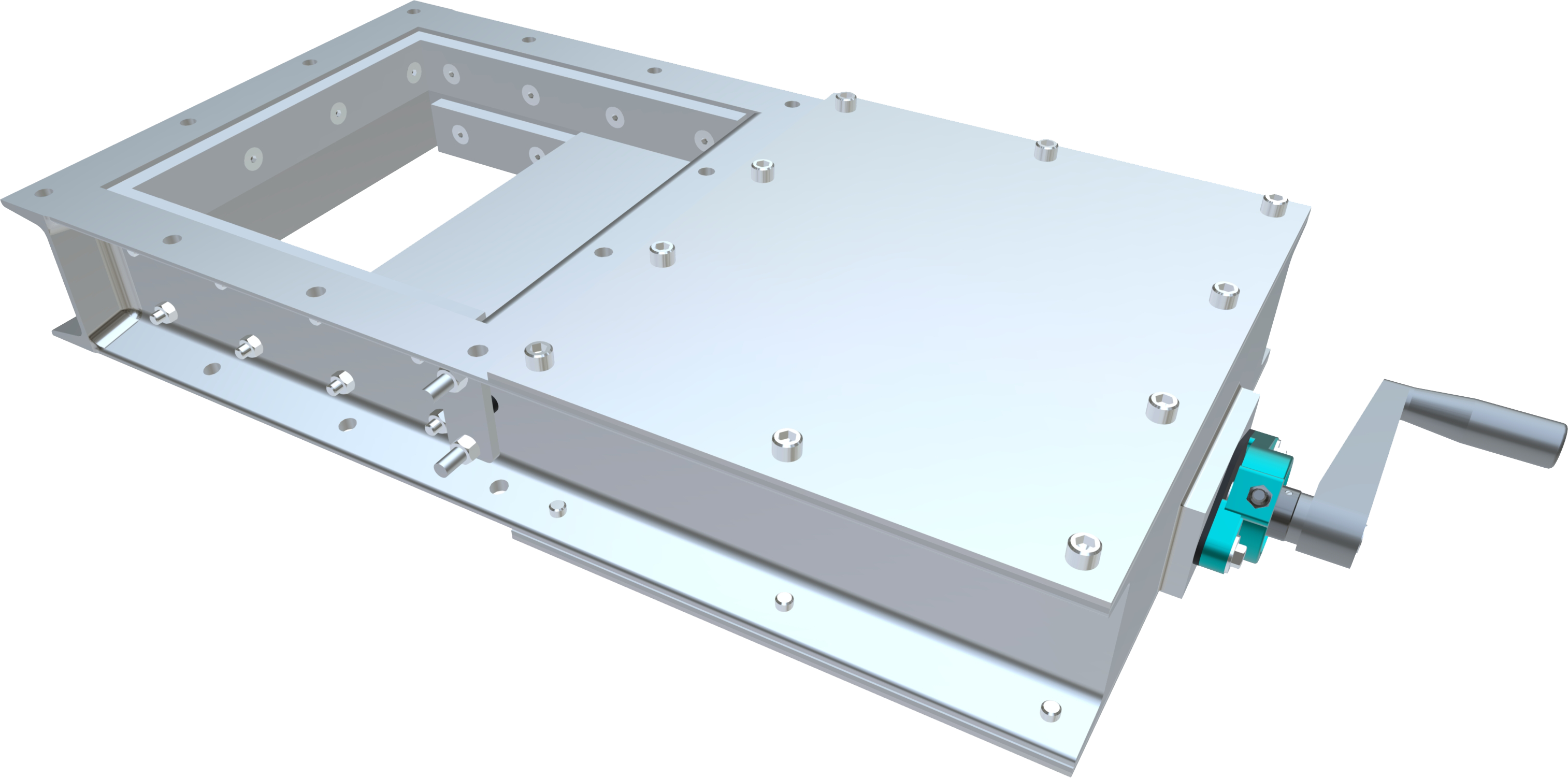

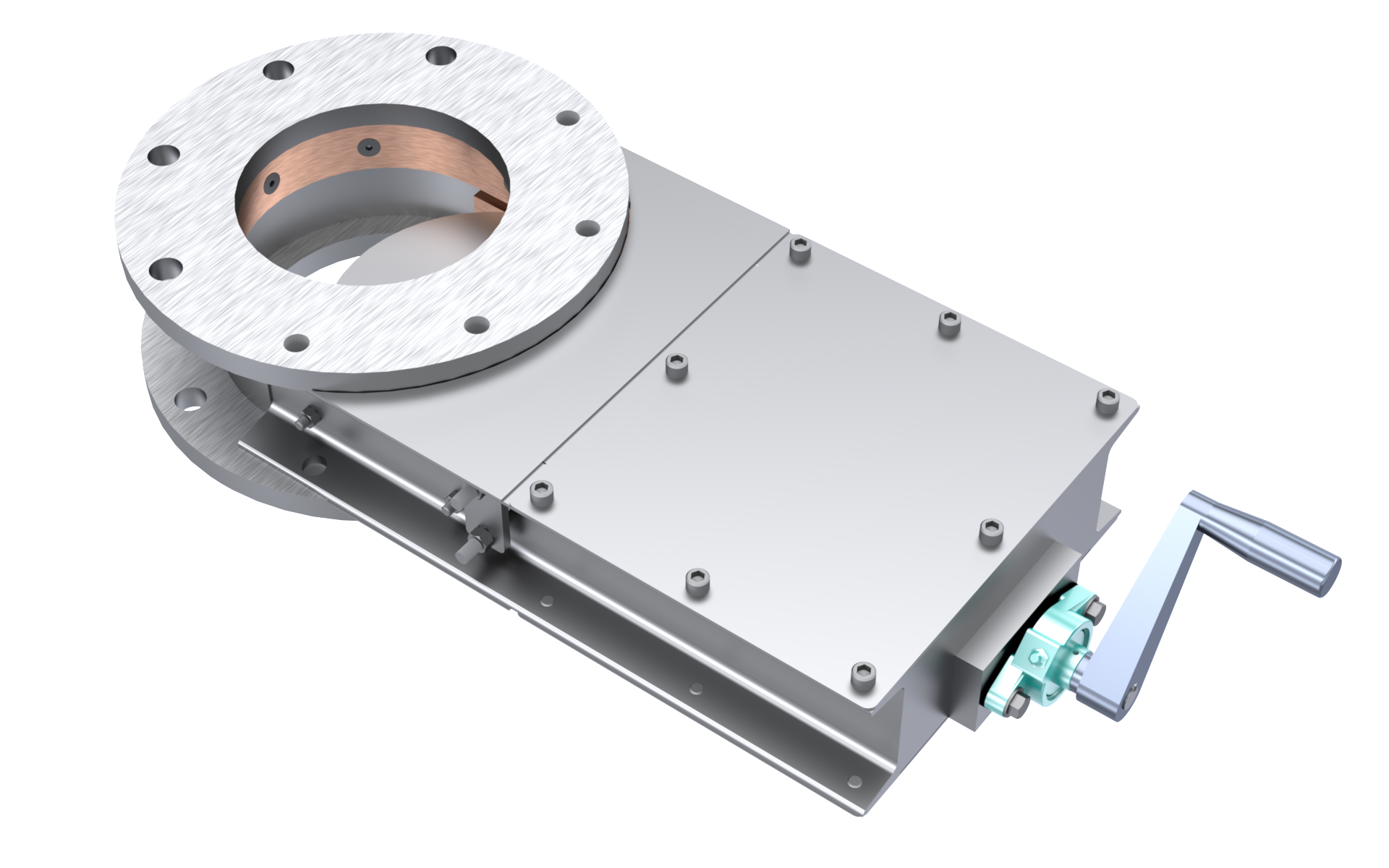

Vortex valves serve many industries including chemical cement coal food. Rising stems lift as the valve opens and lower as the valve closes to provide a visual indication of whether flow is on or off. The maintenance slide gate is manually operated with a low profile. 2 gate valves with stainless steel paddles 16 products.

These gates deliver a positive shut off of material flow for service or replacement of the system rotary valve without the hopper being emptied. Internal cast gate wedges and guides allows for tighter shutoff. Slide gate valve application examples silo discharge slide gate valves are generally actuated by pneumatic pistons. Dec 15 2019 explore josh luftig s board sliding gate on pinterest.

Start typing and press enter to search. Also known as gate valves these gradually open and close to prevent system damage from suddenly starting and stopping flow. Dust tight inside to out it is used to facilitate maintenance operations in dry bulk handling gravity and pneumatic conveying systems. Pull handles open and close faster than wheel handles.

Standard 304 stainless steel gate. The internal design of the valve avoids any build up of solids that would prevent the valve from closing. The bottom of. Home industrial products manual gate valves.

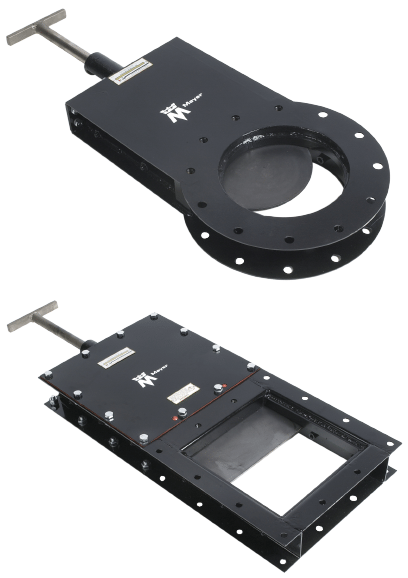

The gates are polished and lapped to attain a greater seal between the gate and both the packing and the seat. Knife and slide gate valves. Generally gates which are other than manually operated will failsafe close if power to the directional valve controlling the gate is interrupted. The knife gate and sliding gate valves help control gravity batch unloading when handling dry free flowing materials.

The stem is isolated from the process media for a longer service life than valves with. Vortex slide gates are designed and engineered with two main principals in mind. They are used for opening and closing product flow automatically to discharge the product to downstream equipment manually operated slidegate valves installed below silos or hoppers are generally used for maintenance operations of equipment like rotary valve screw feeder etc. The slide gate s hard polymer seals compensate for wear unlike the knife gate.

2 gate valves with plastic paddles 24 products.